Improve the production efficiency of anti-epidemic products

After the outbreak, the demand for masks has increased, and the coding efficiency of masks is far lower than the normal shipping speed. Small OEM mask orders have caused problems for mask manufacturers. The traditional pad printing process has slow efficiency and high labor costs.

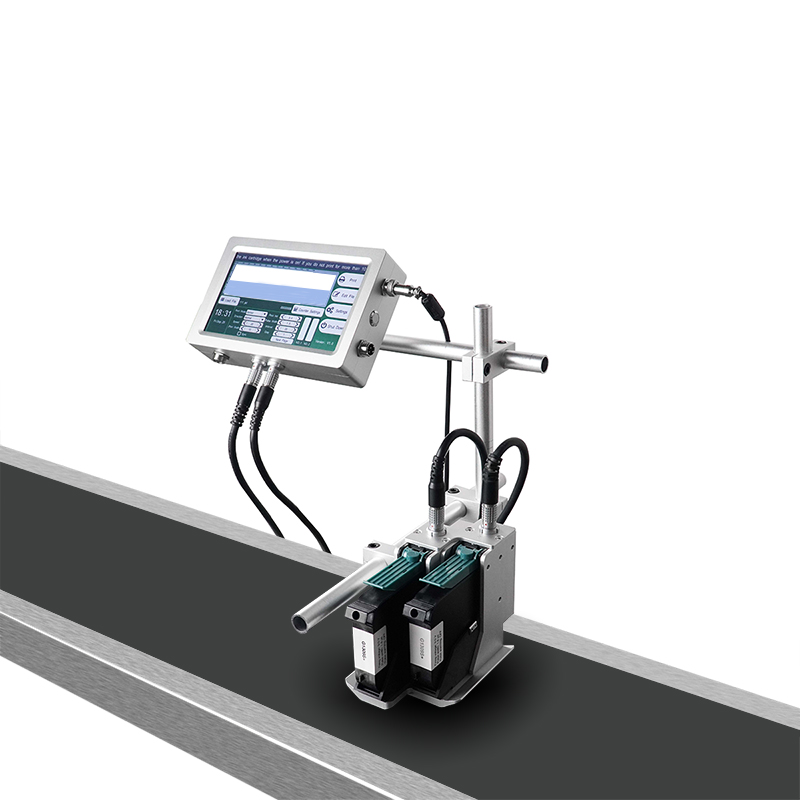

In order to improve the efficiency of the coding link, the company specially organized a research and development team to make a number of adjustments to the inkjet printer, which has reached the goal of being directly mounted on the mask production line, matching the mask production line speed, and truly achieving production and printing. If the code is integrated, it will greatly increase production efficiency, reduce labor costs, shorten the delivery time, and help the production of masks. At the same time, the ink used by the inkjet printer has also passed the testing of international organizations SGS and TUV, and obtained the certificate, which is not affected by respiratory health. influences.