How to Pick up 2D 2.5D 3D Laser Marking Machine

You maybe confused about several type of laser marking machine, like 2D 2.5D and 3D laser marking machine, this article will show you different on software, laser head about 3 different laser marking machine.

Now that the Fiber laser marking machine has developed rapidly and quickly occupied the many market, their differences are mainly distinguishes from applications, core parts. Laser marking machines can be divided into fiber laser machine, Co2 laser machine, UV laser machine etc. Here we just talk about the fiber laser machine. so this article will focus on 2D 2.5D and 3D fiber laser marking machine.

What's 2D fiber laser marking machine?

2D laser marking machine are widely used in many fields. For example, metal marking such as stainless steel, carbon steel, gold, silver, copper, Brass and aluminum, and some plastic engraving such as animal ear tags,Keyboard,polymer,ABS and so on. it widely use in market, BOGONG MINI type laser engraving machine sold very well in market.

Application of 2D laser marking machine:

The fiber laser marking machine available on the market satisfies most marking applications, such as logo making, serial numbers, technical specifications and other designs on metals (copper, iron, steel, stainless steel, titanium, aluminum, gold, silver, Brass Marking alloys, etc.) and ABS, etc. However, the working area of the fiber laser engraving machine mostly is 100*100mm, there have optional lens can bigger the engraving area: such as 70*70mm, 110*110mm, 150*10mm, 200*200mm 300*300mm Most of them are also equipped with low-power laser sources. Such as 20w 30W 50W 100W and so on.

2D laser marking machine model below:

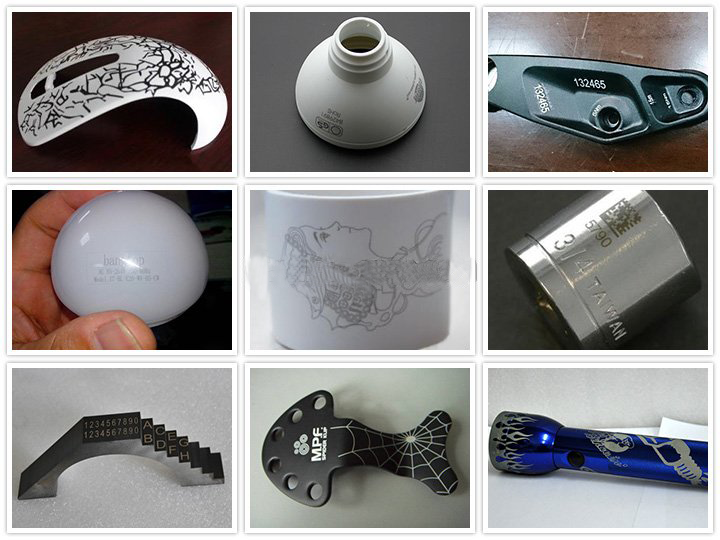

Laser work by 2D laser marking machine show:

But the disadvantage of 2D fiber laser marking machine is that it can only work on a flat surface. The more function is to use the Rotary System, we can also use it to mark some cylinders, such as cups. Or rings, bracelets, etc. Even in this case, there are many limitations on curved markings. So 2.5D and 3D laser marking machines became popular in the market. A large part of it meets many needs of customers. But what is the difference between these three types of machines, the following article will show you.

What's 2.5D fiber laser marking machine?

From technical part, we called it 2.5D because laser head is still with a 2D laser head, but 2.5D with motorized lifting pillar. And galvo head can be controlled by software. software can control laser head move when laser working, so it can achieve 3D marking. it means 3D laser, Z axis mirror inside laser head to move back and forth; 2.5D, Z axis stands for the third mirror to move automatically.

2.5D laser marking machine can finish all 2D laser work and can make 3D laser marking on flat plate. 2.5D CANNOT make 3D marking on curved part.

Lifting pillar of 2.5D laser machine must be motorized type. Because laser head need to re-adjust the focus during marking.

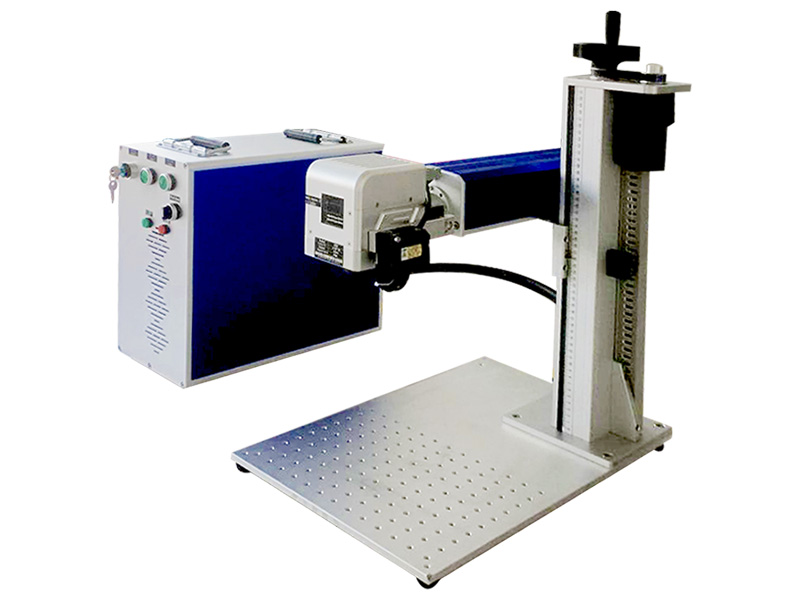

2.5D laser marking machine model below:

Projects of 2.5D Fiber Laser Marking Machine with EZCAD3

What's 3D fiber laser marking machine?

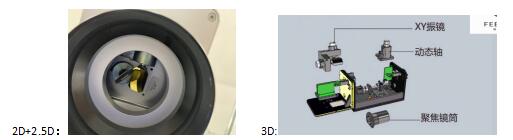

3D means dynamic focusing. Compared with ordinary 2D fiber laser machines, 3D laser marking machines use different Laser head. Ordinary 2D fiber Laser Machine uses 2D galvo scanning head with only two mirrors, while 3D fiber Laser machine uses 3D Dynamic focus scanning head scanning heads with three mirrors. The third mirror can be moved back and forth. This is the key technology of 3D laser marking machine.

Advantages of 3D Fiber Laser Marking Machine

1.High precision of 3D positioning technology, high-speed focusing and scanning system, short pulse, high-peak power and HPRF (High Pulse Repetition Frequency).

2.With friendly operation interface, it is suit for many file formats, such as dxf, plt, cnc, step, iges, etc;

3.High electro-optic conversion efficiency, long life and easy maintenance.

4.Fast marking speed and high processing efficiency.

Applications of Portable 3D Fiber Laser Marker

The 3D suitable for all kinds of metals and nonmetals laser marking on 3D surface. It’s widely used in mobile manufacture, cubic circuits, medical equipments, moulds, 3C electronics, auto parts, electronic communication, etc.

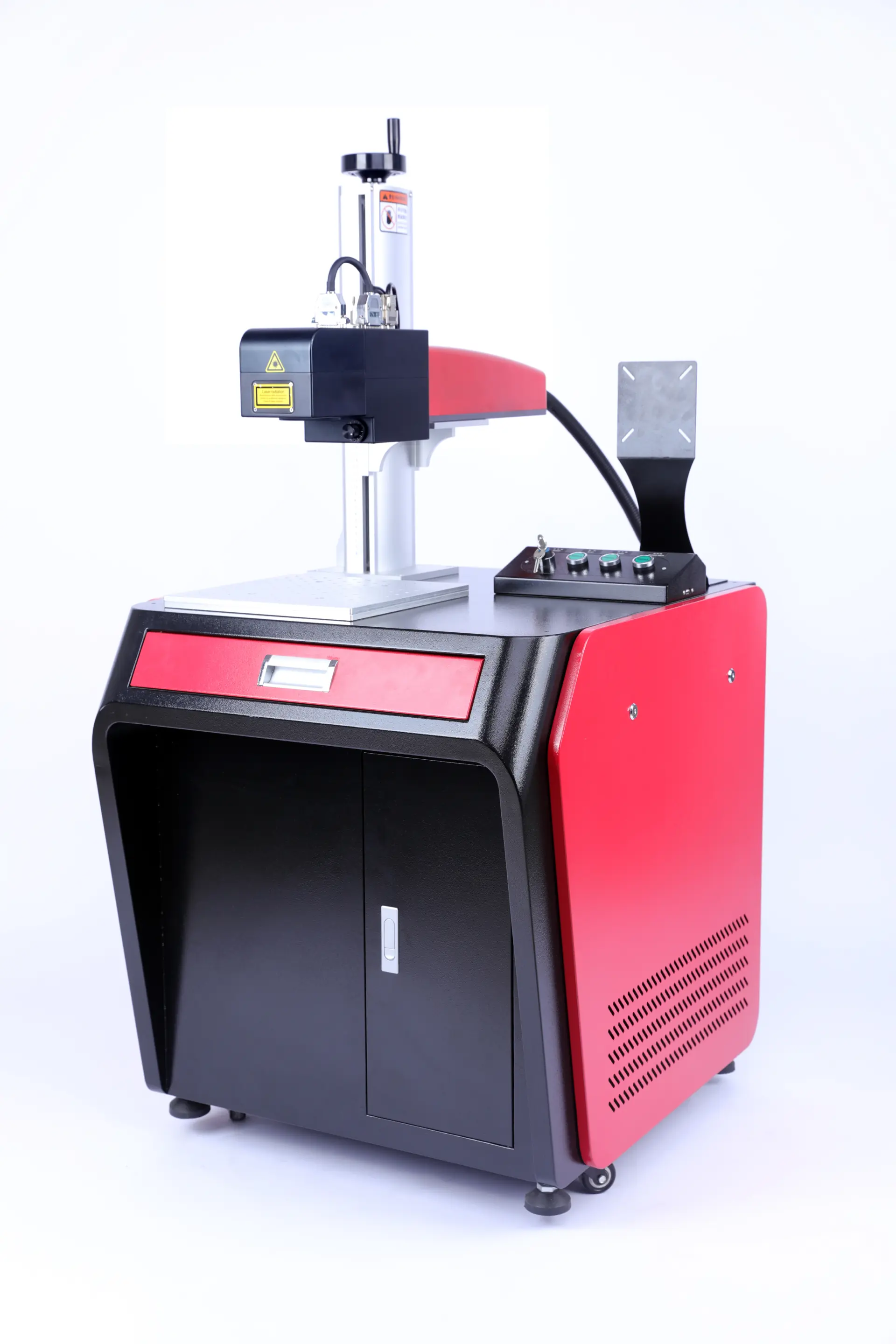

3D laser model below:

Laser works by 3D laser marking machine show:

What's difference between 2D and 2.5D and 3D fiber lasers

1. In appreance of laser head:

In terms of galvanometer: 2D and 2.5D galvanometers are basically the same. The interior consists of two lenses on the X and Y axes. The 3D machine has a larger galvanometer, mainly because there are three lenses inside the galvanometer, which are XYZ-axis lenses.

2.Different on laser marking software and control board about 2D 2.5D and 3D laser marking machines:

Board:

2D standard laser software is EZCAD2 version board, 3D laser marking machine mostly use Lenmark software. Differnt control board, different software, EZcad3 relies on the electric column to realize the autofocus under the premise of fixed workpiece height and focal length, and relies on the electric column to drive the vibrating lens to achieve autofocus. To a certain extent, it imitates the working principle of 3D machine dynamic focus, so why 2.5D machine can do 3D relifs.

Software aspect:

The software version of the 2D machine is EZcad2, the interface is simple and the stability is better.

The 2.5D machine software is an EZCAD3 plane embossed board. 2.5D board is EZcad3 according to the date update as the version number, board model is DLC-M4-2D flat embossed board,

The 3D machine software is Lenmark, which specifies the corresponding board software for Feeltek, sure there also have other 3D software, like BJJCZ EZCAD3 3D version, compare 3D software, 3D lenmark widely use compare with EZCAD 3 3d version, hope they can come to mature soon.

Summary: Funtion aspects about 2D 2.5D 3D laser marking machine:

The functions that 2D machines can achieve are marking, 2D marking and deep marking. The maximum thickness is about 1mm metal sheet cutting. Of course, you can manually adjust the focus to achieve greater thickness cutting, but this is a method, not a machine function, so let’s leave it alone. .

The 2.5D machine can realize the functions of marking, 2D, 3D marking and relief, and theoretically larger thickness cutting (experiment is still needed, but the edge cutting effect is not required under the premise) depending on the height of the workpiece can be set to a fixed value At the same time, the focal length of the field lens of a single format is fixed, so to a certain extent, it is possible to realize a larger thickness cutting through the function setting in the software.

The functions that 3D machines can achieve are marking, 2D, 3D engraving and embossing. However, due to the influence of the field lens, I personally think that the cutting ability is weak and cannot realize the cutting of large thickness metal sheets. The more important advantage is the engraving, precision and effect. .

3D laser engraving machine also called 3D laser marking machine, 3D laser marker, 3D fiber laser engraving machine, it's the most powerful laser engraving machine in market, so if you have several laser work to do, then choose 3D laser machine

If you just sample on marking on flat surface, or rotary marking, and no need 3d relief laser work, then choose 2D laser machine, in the same time, you want marking 3D relief on flat surface, then choose 2.5D laser marking machine.